ABOUT COMPACT CORE

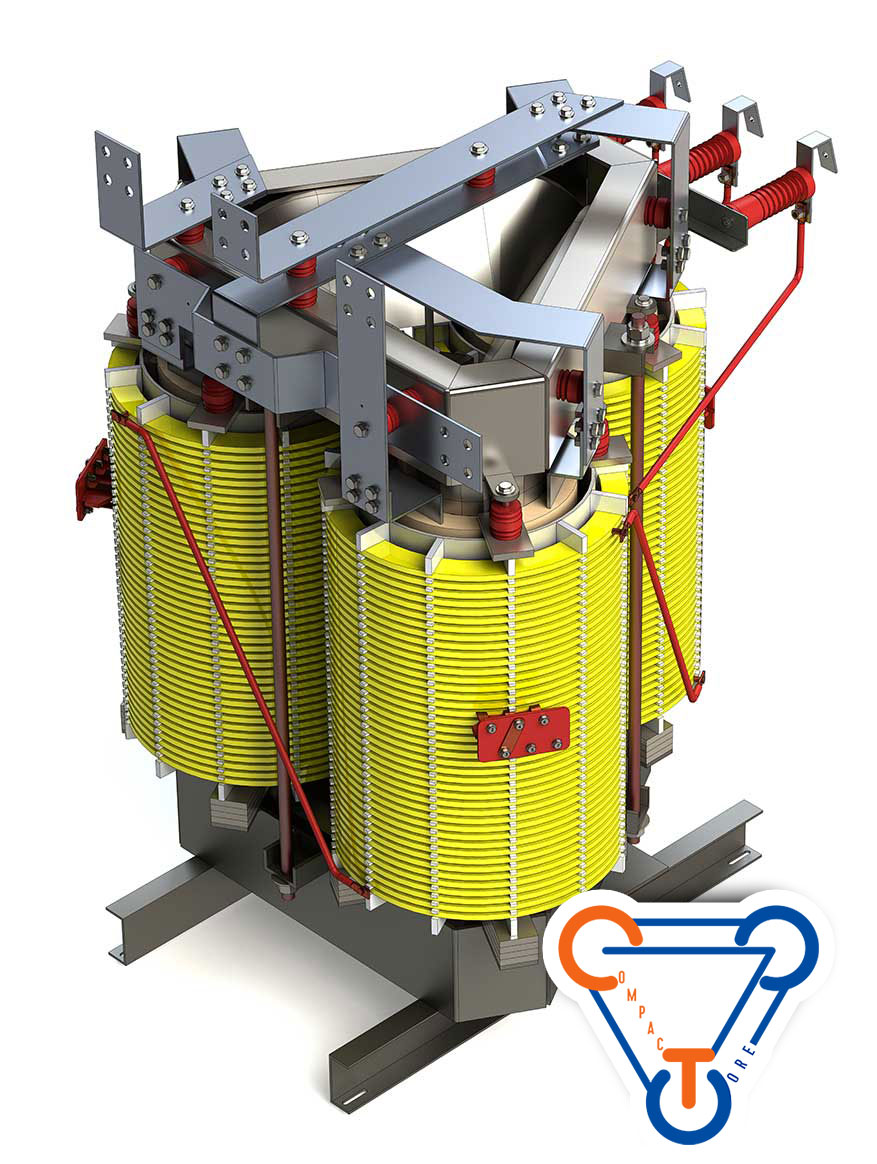

Advancements in manufacturing techniques and the increased performance demands has paved the way for making this cutting-edge triangular wound technology possible. This symmetrical structure produces great savings and benefits in areas such as footprint, weight, reduction in sound levels, harmonic content, stray magnetic fields, improved efficiency levels, and life expectancy extension when comparing a conventional (3-legged stacked core) against a symmetrical triangular (wound core).

Manufacturing Capability – up to 3000KVA and primary voltage class up to 27kV

Both Compact Core and traditional VPI coil technologies – rely on the same insulation types, conductors, and varnish process with temperature ratings of up to 220∞ C

Initial Cost / purchase price – when comparing a Compact Core vs traditional stacked core, if all requirements are equal, the cost will be equivalent between the technologies, but carries the added product benefits of the Compact Core technology

Dimensions / Footprint – The compact core with it’s unique triangular construction allows for a reduction of the overall footprint. Both the height and width from a traditional VPI unit will be reduced. There is a slight increase on the depth of the unit, however the overall width reduction will give a much greater advantage to new projects as well as retrofit capabilities. Approximate reduction in overall footprint size of 15-35%

Weight – Due to the triangular construction, the overall reduction in size leads to less weight which provides easier mobility and installation of the unit – especially for retrofit projects with a weight reduction of 20%

Efficiency – All Compact Core transformers shall meet / exceed DOE 2016 regulations – on top of that, the more efficient units than traditional VPI reduce the operating cost of the transformer throughout its lifetime and provide an affordable, environmentally friendly solution.

Harmonics – The unique design of the Compact Core transformer reduces the harmonics in the transformer. The reduction in harmonics helps reduce additional transformer losses and reduces variability in the transformer output.

Inrush Current – The Compact Core transformer features a magnetically symmetric wound core without perforations. This feature reduces the transformer inrush current which is particularly important for the integrity of multiple transformer banks and modern networked systems with sensitive safety features.

Life Expectancy – The triangular construction of the Compact Core allows for evenly distributed heat dissipation throughout the transformer. In a traditional VPI solution, the hottest winding of the transformer is typically the B phase which is subjected to extra heat. With Compact Core and evenly distributed heat dissipation, this makes may elongate the life expectancy.

Maintenance Cost – the transformers are pretty much identical with regards to care / long term maintenance procedures.

Ecological Impact – due to the triangular construction of the Compact Core, a reduced amount of raw materials are possible.